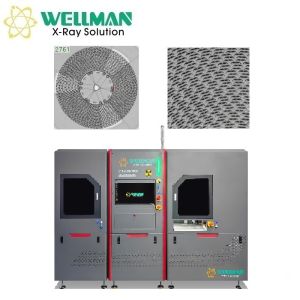

In-line full automatic X-ray parts counter IL-1000

1. Our Advantages

2.1. Permanently updated AI deep learning algorithm for free, support connecting MES,

ERP, WMS, and other management systems.

2.2. Support manual mode, which is used in special cases such as small amount of

reel, overweight & oversize reel, and packaged reel.

2.3. Support AGV docking, realize the whole counting process unmanned.

2.4. Support work order number function and counting record query & statistics.

2.5. 80kV X-ray tube, longer lifetime, maintenance-free.

2.6. Super definition 17” digital flat panel detector (FPD).

2.7. Ultrafast counting, top speed is only 12s per reel.

2.8. Support max 17” (430mm) reel or tray with moisture barrier bags.

3. Speed and Accuracy

Till now, the counting time and accuracy of various sizes of reels as below. It will be

faster and more accurate as our algorithm updates.

| Reel size | Parts size | Quantity | Accuracy | Speed |

| 7”(180mm) | 01005 | 40000 | 99.98% | 14-15s |

| 7”(180mm) | 0201 | 10000 | 99.99% | 13-15s |

| 7”(180mm) | 0402 | 10000 | 99.99% | 13-15s |

| 7”(180mm) | 0603 | 5000 | 99.99% | 12-15s |

| 10”(254mm) | 1206 | 5000 | 99.99% | 12-15s |

| 15”(380mm) | 1206 | 10000 | 99.99% | 12-15s |

2. Hardware Parameters

| X-ray source | Type | Microfocus |

| Max tube voltage | 80kV |

| Max tube current | 700μA |

| Focal spot size | 30μm |

Flat panel

detector | Type | Super definition digital FPD |

| Effective area | 430mm*430mm |

| Pixel size | 139μm |

| Resolution | 3072*3072 |

Reel/tray

counting | Max size | Auto mode 15”(380mm),manual mode 17”

(430mm) |

| Max thickness | Auto mode 50mm,Manual mode 80mm |

| Min parts size | 01005 |

| Speed | 12-15s |

| Accuracy | 01005≥99.98%,0201&above ≥99.99% |

| Media type | Reel materials,tray materials with moisture-

proof bag |

| Equipment | Dimensions | 2700mm (L)*1400mm (W)*1900mm(H) |

| Weight | 3000kg |

| Power supply | AC110-220V 50/60HZ |

| Max power | 4800W |

| Industrial PC | I7 CPU,16G RAM,256G SSD+4T HDD |

| Displayer | 24”HDMI LCD |

Management

system

connection | MES,ERP,etc. |

| Workflow | Loading | After the reel vehicle is pushed in,the

manipulator automatically loads,supporting 7

to 15 inches of reel |

Max loading

quantity | 200 reels (7"with 8mm thickness) |

| Barcode scanning | Can scan barcode,QR code |

| Reel transfer | Automatic belt transfer |

| Labelling | Automatically print and paste labels after

counting,and upload data automatically |

| unloading | The manipulator automatically put into the reel

vehicle |

| Safety | Radiation leakage | No leakage,international standard:≤1μSv/h |

Back door safety

interlock | Once users open the back door,X-ray tube will

power off immediately.When the back door is

open,users can't turn on the X-ray |

| Emergency stop | In front of the operation position,press to

power off |

4. Working Principle

5. Artificial intelligence deep learning algorithm

Our counting software uses a powerful artificial intelligence deep learning algorithm. No

need to bind components to algorithm, we use AI to automatically identify components

and automatically apply algorithm. The algorithm can learn the counted component data,

such as:

1. Aspect ratio

2. The angle of each corner of the component;

3. Slope between components from inside to outside;

4. Deformation of component images from the inside to the outside, etc.

As the number of components counting increases, the results become more and more

accurate. When we need to count similar components, or larger trays, we can easily

handle it

6. Cloud database

Every Wellman X-ray counter can connect to our cloud database. The data and images

of the machine will be uploaded to the cloud, and the machine will automatically

download the latest database. Our engineers also optimize the algorithm in the

background according to the images and data collected by each machine, and regularly

update it to the database for customers.

Over time, the accuracy of counting will be closer to 100%, and the coverage of

component types will become wider and wider. When a machine counts a new kind of

component, if the data of this kind of component is stored in our database, our software

can directly call the data, which brings users higher efficiency, accuracy and coverage.

7. Sample images